New ChromaBioColor Masterbatch from Chroma Color for “Difficult to Recycle” Parts

Companies in the plastic’s industry continues to look for color concentrate solutions to meet sustainability goals. To support these customers Chroma Color’s technical team continues to develop additional options. Recently, a customer was looking for a partner to come up with a color masterbatch using a PHA (polyhydroxyalkanoates) biobased polyester that would comply to *ASTM D-6400/*DIN EN13432 Bio-Composting standards.

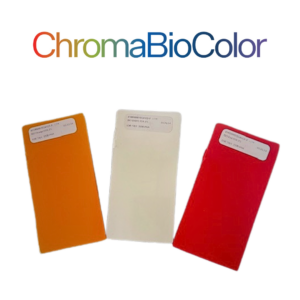

The Chroma Color Technology team developed three new colors for our customer using a specifically designed carrier resin for a masterbatch:

41OR0001SC41CO-F Orange 50/1

41RD0001SC41CO-F Red 50/1

41WH000141CO-F White 50/1

*ASTM D6400 outlines the standard requirements for the biodegradation of solid materials through composting, specifically tailored for labeling plastics intended for aerobic composting in municipal or industrial settings.

*DIN EN 13432 specifies the requirements and procedures for determining the compostability and aerobic treatability of packaging (and its materials).

About PHA’s: are a family of biobased and biodegradable polyesters made by bacterial fermentation. PHACT biopolymers were chosen for this project are plant-based and feature a sustainable manufacturing process. Alone or when blended with other polymers, they dramatically improve environmental characteristics while enhancing physical properties in a broad range of consumer applications. This material is considered to be thermally stable in the normal and customary processing range of 185- 200 Cº. Extended polymer and concentrate residence time in the process equipment may require that process temperature profiles be reviewed and/or adjusted to insure a proper and suitable product.

Click here to download the brochure : https://chromacolors.com/wp-content/uploads/2024/05/Chroma-PHA-Color-Masterbatch-Final-LR.pd

Chroma Color:

Chroma Color Corporation is a leading specialty color and additive concentrate supplier serving diverse markets, including wire and cable, packaging, healthcare, pharmaceutical, consumer products, and others.

With the recent acquisition of Epolin, Chroma Color is now the recognized leader in the near-infra-red (NIR) absorptive dye industry, producing proprietary blends to suit the eye protection and light management sectors.

Chroma Color’s growth strategy includes robust organic and inorganic growth through nine acquisitions over three years. Chroma’s extensive technical leadership and manufacturing expertise, coupled with its game-changing colorant, has delighted customers for over 50 years.