The Challenge:

Companies that manufacture exterior plastics products, such as plastics chairs, playground equipment, decking, fencing, siding, windows, etc., know they become hot to the touch and can fail earlier due to long-term exposure to solar rays. This is especially true for products manufactured with dark colors.

Why?

Dark colors absorb more energy from solar rays compared to lighter ones. These higher absorption of rates solar rays makes dark plastic products hot to the touch and can lead to early failure.

There are three measurements to take under consideration when choosing a color: TSR, E, and SRI values.

- TSR- Total Solar Reflectance is expressed as a percentage between 0 and 100%. These rates indicate a products ability to reflect solar energy.

- E- Infrared Emittance is rated between 0 and 1 and rates the ability of a product to cool itself.

- SRI -Solar Reflective Index combines TSR x E. SRI index is from 0 (standard black) to 100 (standard white).

Luckily, there are solutions available to prevent this heat-buildup and failure.

The Solution:

Chroma Color® has decades of experience in providing customers with color concentrates for exterior durable goods that must withstand elements for an extended period. Today, Chroma Color® offers manufacturers of exterior plastic products formulations that reduce Total Solar Reflectance (TSR). This technology from Chroma Color® minimizes the heat build-up on the surface of dark colored plastic products.

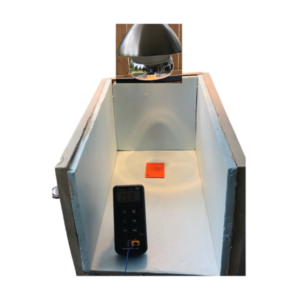

Photo Caption: Chroma Color®’s ASTM testing apparatus for measuring temperature rise

To ensure your color concentrates meets the criteria for reducing heat build-up on dark plastics, our technical team uses the ASTM D-4803-97 method to measure the temperature increase. This testing provides useful comparative data on heat build-up of various polymers and color formulations. Carbon black plastic color typically has the highest rating of heat buildup. Therefore, this ASTM test method compares the heat buildup of your chosen color against a carbon black plastic control sample.

To inquire about Chroma Color®’s infrared-reflecting color concentrates and this testing method contact us here: https://chromacolors.com/contact-us/

Chroma Color®:

Chroma Color® Corporation is a leading specialty color and additive concentrate supplier serving diverse markets, including wire and cable, packaging, healthcare, pharmaceutical, consumer products, and others.

With the recent acquisition of Epolin, Chroma Color® is now the recognized leader in the near-infra-red (NIR) absorptive dye industry, producing proprietary blends to suit the eye protection and light management sectors.

Chroma Color®’s growth strategy includes robust organic and inorganic growth through nine acquisitions over three years. Chroma’s extensive technical leadership and manufacturing expertise, coupled with its game-changing colorant, has delighted customers for over 50 years. For additional information, please visit www.chromacolors.com.