Over the past decade, consumer packaged goods (CPG) companies have increasingly prioritized cost reduction. While efforts have largely focused on innovations in package design and construction, attention has also shifted to other cost factors, such as colorants and design features.

Traditionally, CPG companies relied on the expertise of their molding partners in these areas. However, in recent years, colorant suppliers have taken a more proactive approach, presenting their cost-saving solutions directly to corporate decision-makers.

This shift has led to the growing adoption of liquid color in the packaging industry, because in some cases it has demonstrated ability to lower let-down ratios and reduce overall costs compared to traditional color concentrates. Despite these benefits, many processors remain hesitant due to the housekeeping challenges and high scrap rates often associated with liquid color.

Overview of Liquid Color

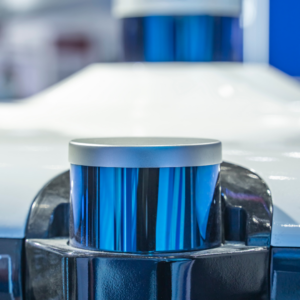

Advancements in liquid colorant dosing systems over the past decade have greatly enhanced their user-friendliness, providing cleaner and easier handling solutions tailored to industry requirements. Liquid colorants have long delivered vibrant hues at low use rates, offering excellent color distribution ideal for tints and transparent applications. For instance, liquid colorants can achieve some pearlescent and metallic effects, enhancing shelf appeal for brand owners and packaging designers.

Additionally, liquid colorants can be processed at lower temperatures than traditional masterbatch, avoiding heat history degradation and eliminating pre-decomposition concerns. This makes them a reliable and efficient choice for achieving striking visual effects without compromising material integrity.

On paper, liquid color may seem cost-effective, promising aesthetic benefits at reduced expenses. However, the hidden drawbacks often complicate the overall production process.

Challenges of Liquid Color:

- Complex Equipment Needs: Liquid color requires specialized pumps and hoses to integrate properly, complicating operations. For example: If a line stops and the equipment isn’t tied into the screw signal correctly the liquid pump will keep dosing, flooding the barrel with color.

In addition, Liquid is delivered through polyethylene tubes which can wear out and rupture, causing spills. Additionally, these tubes are consumables not provided by the manufacturer and need to be purchased by the molder.

- Handling Inefficiencies: High risks of spills and constant equipment maintenance make liquid color messy and inefficient. For example, liquid color often causes screw slippage, especially at higher letdown ratios, which results in the constant monitoring of the machine and severe delays in production. When a liquid container empties, it often does so with no warning. This requires the machine to be stopped until the new container is ready to run and again, causes delays in production.

Liquid color also has a tendency when used for long periods of time to cause staining of the screw of the manufacturing machine The limited shelf life and frequent separation issues lead to waste.

- Resin Compromises: Liquid color displaces resin, requiring more material to maintain shot weight, which can increase costs unexpectedly. For instance, a lower letdown ratio (LDR) may look appealing but adds resin expenses, diminishing perceived savings. In addition, liquid needs to be stored in temperature-controlled areas. Additionally, shipping liquid in cold weather can allow it to freeze, ruining the color.

- Waste & Sustainability: Liquid color cannot be fully used from containers, leading to scrap rates of up to 10%. Combined with disposal issues requiring hazardous waste removal, this contributes significantly to environmental concerns. Plus, when using regrind, the fines can mix with liquid and create clumps that block the flow of pellets through the feed throat.

The Efficiency of New Technology of Color Concentrates

Newer color concentrate technology offers a superior alternative that minimizes these inefficiencies. Unlike liquid color, advanced pelletized concentrates eliminate the mess, waste, and complex equipment while offering consistent color results across various applications.

Advantages of Color Concentrate Pellets:

- Sustainability: Liquid color’s carbon footprint is significant, with oil-based carrier systems adding to environmental impact. This technology’s carrier system uses fewer raw materials and reducing carbon output.

- Ease of Use: These pellets integrate seamlessly into production lines, compatible with standard feeding systems. No pumps, no spills—just easy, efficient coloring.

- Maximized Usage: Unlike liquid color, this technology allows for 100% use, reducing waste and ensuring every pellet contributes to the product.

- Reduced Scrap and Downtime: Liquid color systems often cause scrap and require frequent purging, but these color concentrates pellets enable faster color changeovers with minimal waste, optimizing production efficiency.

- Simplified Disposal: These pellets are also non-hazardous and disposed of in traditional waste streams, unlike liquid color, which needs special disposal and adds to a higher carbon footprint.

Comparing the Environmental Impact

Packaging and Shipping: A 1,000-pound order of this technology is packaged in Sustainable Forestry Initiative (SFI) rated cardboard and weighs about 25 pounds including the lid. Most processors have liquid color delivered in 5-gallon buckets so they can agitate the color before use. Obviously, pellets do not need to be agitated. To ship 1,000 pounds of liquid color in plastic buckets is roughly 100 pounds of packaging material used to ship the liquid color vs 25 lbs. of the new pellet technology.

Some liquid companies have touted a “Pump in a Drum” system for reusable packaging, but keep in mind doing this adds another shipment back to the manufacturer and increases the carbon footprint of the packaging in the life cycle assessment.

“Cradle to Grave” Sustainability: The complete lifecycle of this newer color concentrate is designed to be environmentally friendly, with fewer emissions and more efficient waste management. Liquid color’s extra shipments for hazardous waste disposal and inefficient usage only add to its environmental burden.

Why Chroma Color®’s G-Series Is the Future

Chroma Color®’s patented G2 and G3 technologies represent a breakthrough in the plastics industry. By combining the dispersion quality of liquid color with the ease and efficiency of pellets, G2 and G3 achieve vibrant, uniform colors at lower letdown ratios. This means manufacturers benefit from cost savings without sacrificing quality.

To explore how G2 and G3 can transform your production, visit: Chroma Color® G-Series.

About Chroma Color® Corporation

Chroma Color® delivers unparalleled color solutions for industries ranging from packaging to healthcare. With a focus on innovation and customer satisfaction, our G-Series technology and strategic growth have established us as industry leaders for over 50 years. Learn more at www.chromacolors.com.